Dust Collector

Professional Powder Handling Solutions

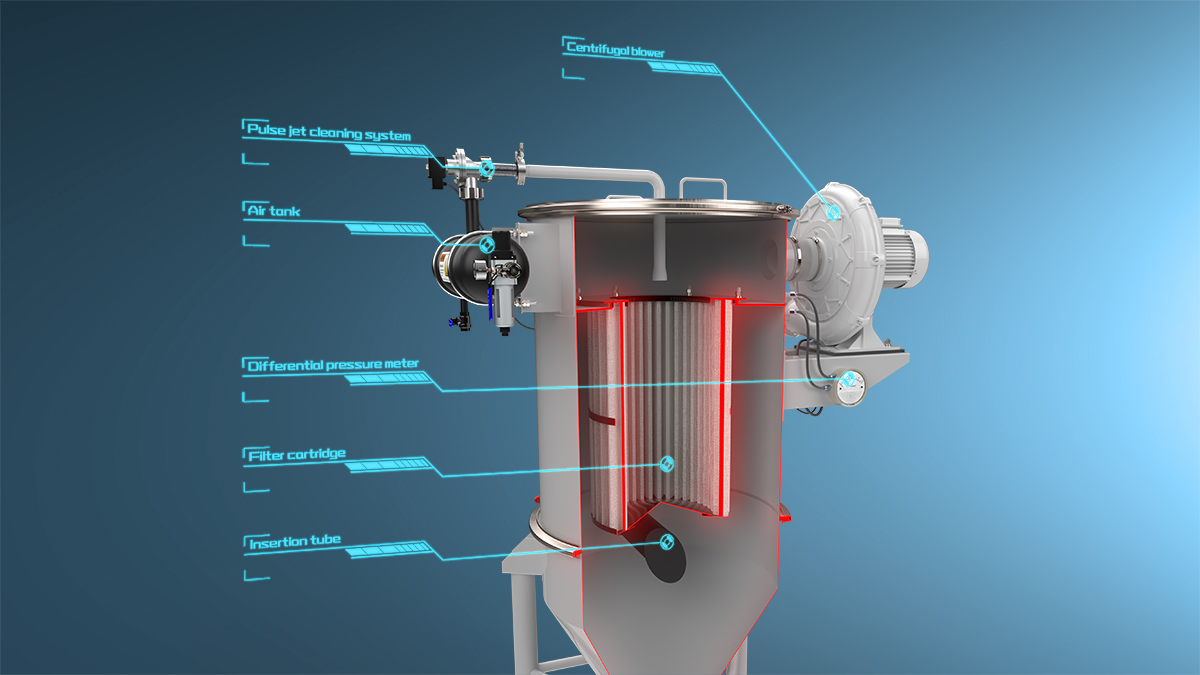

Dust Collector

Designed to enhance air quality in industrial and commercial settings by removing particulate matter from air or gas streams.

REF. 001/809

Available in store

Square model

| Model name | Fan power, kW | Filter area, m² | Airflow, m³/h |

|---|---|---|---|

| BDC-12 | 1.5 | 12 | 1,200-1,800 |

| BDC-18 | 2.2 | 18 | 1,300-2,200 |

| BDC-24 | 2.2 | 24 | 1,500-2,400 |

| BDC-36 | 3.0 | 36 | 2,500-3,500 |

| BDC-48 | 3.7 | 48 | 3,500-5,000 |

| BDC-60 | 5.5 | 60 | 4,500-6,000 |

| BDC-72 | 7.5 | 72 | 5,500-7,000 |

| BDC-100 | 11 | 100 | 8,000-12,000 |

| BDC-150 | 15 | 150 | 12,000-15,000 |

| BDC-200 | 22 | 288 | 15,000-20,000 |

Circular model

| Model name | Fan power, kW | Filter area, m² | Airflow, m³/h | Outer diameter, mm |

|---|---|---|---|---|

| BD-06 | 1.5 | 6 | 1,200 | 720 |

| BD-10 | 1.5 | 6 | 1,200 | 720 |

| BD-20 | 2.2 | 10 | 2,100 | 850 |

| BD-30 | 5.5 | 30 | 3,800 | 1,000 |

| BD-50 | 7.5 | 50 | 4,500 | 1200 |

| BD-100 | 11.0 | 100 | 5,100 | 2,400 |

Warehouse roof model

| Model name | Filter area, m² | Outer diameter, mm | Height, mm | Weight, kg |

|---|---|---|---|---|

| BDH-015 | 0.15 | 133 | 320 | 6.5 |

| BDH-045 | 0.45 | 219 | 380 | 18 |

| BDH-160 | 1.6 | 305 | 460 | 23 |

| BDH-250 | 2.8 | 355 | 610 | 35 |

Circular model

| Model name | Fan power, kW | Filter area, m² | Airflow, m³/h | Outer diameter, mm |

|---|---|---|---|---|

| BD-06 | 1.5 | 6 | 1,200 | 720 |

| BD-10 | 1.5 | 6 | 1,200 | 720 |

| BD-20 | 2.2 | 10 | 2,100 | 850 |

| BD-30 | 5.5 | 30 | 3,800 | 1,000 |

| BD-50 | 7.5 | 50 | 4,500 | 1200 |

| BD-100 | 11.0 | 100 | 5,100 | 2,400 |

Vacuum feeder, also known as vacuum conveyor,

is a dust-free closed pipeline transportation equipment that uses vacuum suction to

transport granular and powdery materials. It uses the air pressure difference between

the vacuum and the ambient space to flow gas in the pipeline at a specific pressure.

Drive the movement of powdery materials to complete the transportation of powders.

Vacuum transportation is a closed pipeline transportation.

This transportation method can eliminate dust environmental pollution, improve the working environment,

reduce the pollution of the environment and personnel to materials, and improve cleanliness; pipeline

transportation takes up little space and can complete powder transportation in small spaces, not limited

by the conveying distance.

Vacuum feeding machine

| Model name | Conveying capacity (5m), kg/h | Conveying capacity (8m), kg/h | Power, kW | Feeding pipe ID, mm | Air pipe ID, mm | Weight, kg |

|---|---|---|---|---|---|---|

| VF-400 | 400 | 280 | 2.2 | 40 | 50 | 80 |

| VF-600 | 600 | 400 | 4 | 50 | 63 | 100 |

| VF-1000 | 1000 | 700 | 5.5 | 63 | 75 | 130 |

Gas-solid separator for positive pressure conveying

| Model name | Filter area, m² | Backflush air bag volume, L | Solenoid valve quantity | Outer diameter, mm |

|---|---|---|---|---|

| BG-06 | 6-8 | 20 | 5 | 1,000 |

| BG-06 | 9-12 | 20 | 5 | 1,000 |

| BG-06 | 12-15 | 23 | 7 | 1,200 |

| BG-06 | 15-20 | 23 | 7 | 1,200 |

| BG-06 | 20-30 | 26 | 9 | 1,500 |

| BG-06 | 30-50 | 35 | 11 | 2,000 |